eMMC chip-level repair is one of the most advanced areas of mobile phone repairing. It goes far beyond screen replacement or battery changes. At this level, technicians work directly on the phone’s memory chip to fix problems related to boot failure, dead phones, data corruption, and storage errors.

This guide is written for allgsmtip.com readers who want clear, practical, and real-world information—whether you are learning chip-level repair or upgrading your professional toolkit.

We will cover:

- What eMMC chip-level repair actually means

- Why special tools are required

- A complete and updated list of tools (2025)

- Beginner vs professional setups

- Common mistakes to avoid

- Safety and workflow tips used in real repair labs

What Is eMMC Chip-Level Mobile Repair?

eMMC (Embedded MultiMediaCard) is the internal storage chip in most Android phones and some older iPhones. It stores:

- Android OS or iOS system files

- User data (apps, photos, videos)

- Boot and firmware partitions

When this chip develops faults, the phone may show issues such as:

- Stuck on logo

- Dead phone (no power)

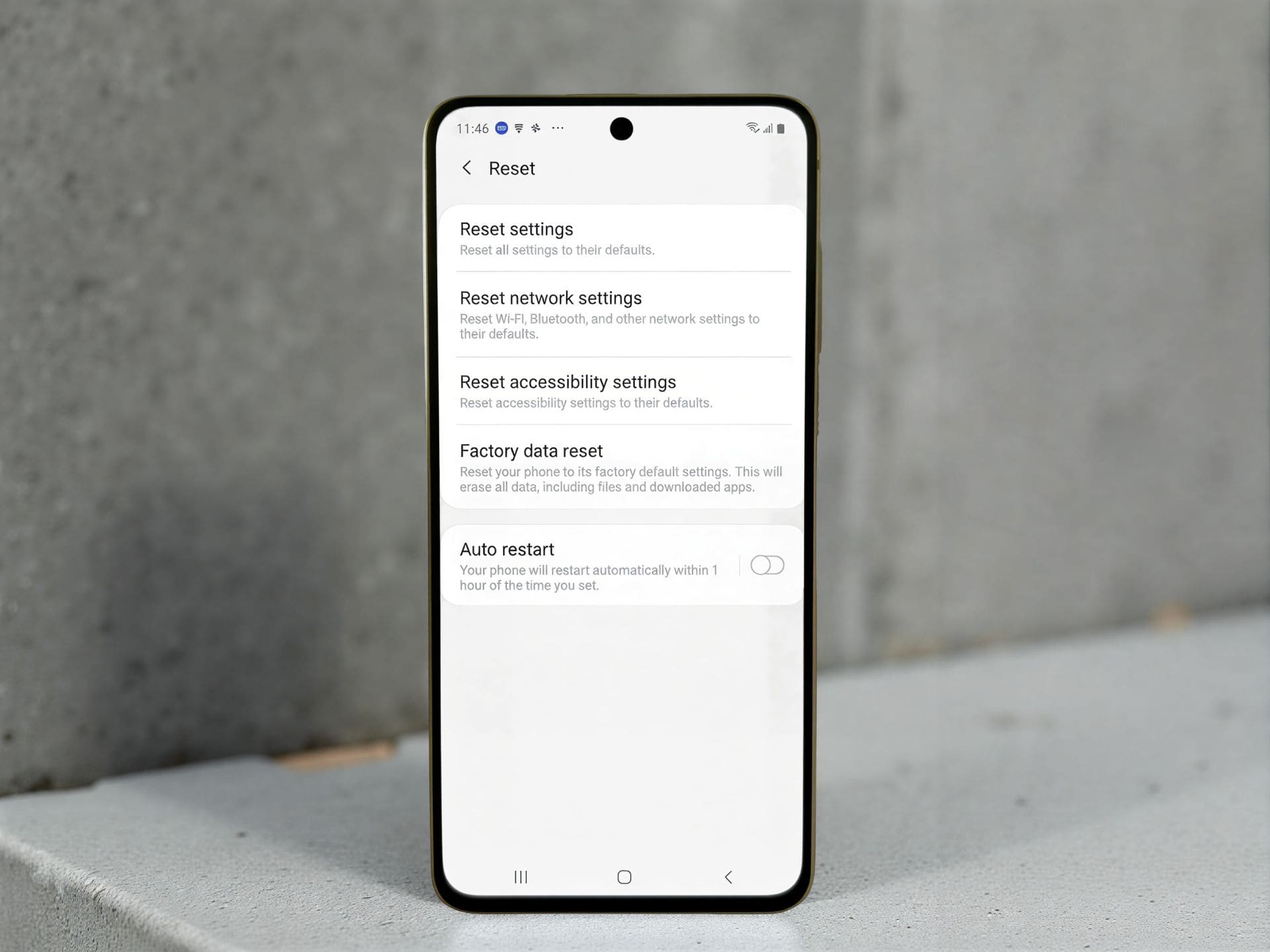

- Auto restart loop

- Storage not detected

- “Invalid IMEI” or corrupted firmware

eMMC chip-level repairing means diagnosing, removing, reprogramming, or replacing the eMMC chip directly on the motherboard.

This work cannot be done with basic mobile repair tools. It requires precision instruments and specialized programming tools. There are various levels in mobile repairing – L1, L2, L3 and L4 based on their difficulty level.

Why Specialized Tools Are Required for eMMC Repair

eMMC chips are:

- Extremely small (often BGA type)

- Soldered directly to multilayer PCBs

- Sensitive to heat, static electricity, and voltage

Without proper tools:

- Pads can lift from the motherboard

- Data can be permanently lost

- The board can become irreparable

That’s why professional chip-level technicians rely on a carefully selected toolset designed specifically for memory-level work. While if you need a general list of tools required for cell phone repair, read our guide on essential and basic cell phone repair tools needed for technicians.

Core Categories of eMMC Chip-Level Repair Tools

Before listing individual tools, it helps to understand the categories they fall into:

- Soldering & Rework Tools

- Chip Programming & Reading Tools

- Testing & Measurement Tools

- Microscope & Visual Inspection Tools

- Support, Safety & Consumables

Each category plays a critical role in a successful repair.

Essential Soldering & Rework Tools for eMMC Repair

1. Hot Air Rework Station

Used to safely remove and reinstall eMMC chips.

Key features to look for:

- Digital temperature control

- Adjustable airflow

- Stable heat output

Why it matters:

Uneven or excessive heat can destroy the chip or motherboard layers.

2. Precision Soldering Station

Required for:

- Jumper wire connections

- Pad repair

- Small component soldering near the eMMC area

Tip: Always use a fine conical or knife tip for chip-level work.

3. PCB Preheater

Preheats the motherboard from below.

Benefits:

- Reduces thermal shock

- Prevents board warping

- Allows lower hot-air temperatures

This tool is especially useful for multilayer boards found in modern smartphones.

4. BGA Reballing Kit (for eMMC)

Includes:

- Reballing stencils

- Solder balls (various sizes)

- Flux and alignment tools

Why rebelling is important:

After chip removal, solder balls must be restored before reinstalling the eMMC.

eMMC Programming and Reading Tools (Most Critical)

5. eMMC Programmer Box

This is the heart of chip-level repair.

Used to:

- Read eMMC data

- Write firmware and partitions

- Repair corrupted boot areas

- Backup user data (when possible)

Common capabilities:

- ISP (In-System Programming)

- Direct chip reading

- Pinout-based connections

6. ISP Cable Set

Allows reading and writing eMMC without removing the chip.

Advantages:

- Faster workflow

- Lower risk of board damage

- Useful for supported models

Limitation:

Not all phones support stable ISP access.

7. eMMC Adapters & Sockets

Used when the chip is removed from the board.

Includes:

- BGA adapters

- Clamp sockets

- Test sockets for different chip sizes

These ensure secure electrical contact during programming.

Inspection and Diagnostic Tools

8. Microscope (Mandatory)

Chip-level repair is impossible without magnification.

Recommended features:

- 7x–45x zoom

- LED ring light

- Stable stand

Used for:

- Pad inspection

- Solder joint quality

- Cracked trace detection

9. Digital Multimeter

Used to check:

- Continuity

- Short circuits

- Voltage lines

- Ground resistance

Real-world use:

Before connecting a programmer, always confirm that the eMMC power lines are not shorted.

10. DC Power Supply

Helps analyze phone behavior during boot attempts.

Why it’s useful:

- Shows current draw patterns

- Helps identify dead or shorted boards

- Confirms whether the eMMC is responding

Supporting Tools That Make a Big Difference

11. Flux (No-Clean, Chip-Level Grade)

Improves solder flow and prevents oxidation.

Important:

Low-quality flux can leave residue and cause corrosion.

12. Solder Paste and Solder Wire

Used during:

- Pad repair

- Jumper work

- Reballing corrections

Always use lead-free solder compatible with smartphone boards.

13. Precision Tweezers & Blades

Required for:

- Chip lifting

- Cleaning pads

- Removing underfill material

14. PCB Holder / Board Fixture

Keeps the motherboard stable during heating and soldering.

This reduces accidental movement and misalignment.

15. ESD Protection Tools

Includes:

- ESD mat

- ESD wrist strap

Why it matters:

Static discharge can silently damage memory chips.

Optional but Highly Useful Tools

These are not mandatory but improve efficiency and success rate:

- Ultrasonic cleaner (for corrosion cases)

- Underfill remover chemicals

- Thermal camera (advanced diagnostics)

- Backup power activation boards

Beginner vs Professional eMMC Tool Setup

Beginner Setup (Learning Phase)

- Hot air rework station

- Soldering station

- Microscope

- Multimeter

- Entry-level eMMC programmer

- Basic ISP cables

This setup is enough to understand concepts and practice safely.

Professional Setup (Repair Lab)

- Advanced hot air + preheater

- High-quality microscope

- Multiple eMMC adapters

- Reliable programmer with software updates

- DC power supply

- Full ESD protection

This setup is required for customer devices and data-sensitive repairs.

Common Mistakes in eMMC Chip-Level Repair

Avoid these frequent errors:

- Overheating the chip or board

- Skipping data backup before writing firmware

- Wrong ISP pin connections

- Using excessive solder or flux

- Ignoring power line testing before programming

Most failed repairs happen due to haste, not lack of tools.

Safety and Best Practices

- Always backup data when possible

- Use low airflow with controlled temperature

- Label removed chips immediately

- Clean flux residue after work

- Never rush eMMC programming steps

These habits protect both the phone and your reputation as a technician.

Is eMMC Repair Still Relevant in 2025?

Yes. While newer phones use UFS storage, millions of Android devices worldwide still rely on eMMC. Entry-level and mid-range smartphones continue to use it due to lower cost.

For technicians:

- eMMC repair remains high-demand

- Skill competition is lower than screen repair

- Profit margins are better for advanced repairs

Final Thoughts

eMMC chip-level mobile repair is not about owning expensive tools. It is about using the right tools correctly with patience and understanding.

If you are serious about chip-level work:

- Start small

- Learn signal flow and memory basics

- Practice on scrap boards

- Upgrade tools gradually

With the correct approach, eMMC repair can become one of the most valuable skills in mobile phone repairing.